A simple filter for rare earth elements will ensure a clean domestic supply of these crucial metals

Rare earth elements sustain the Information Age, and securing a supply of these metals has become a matter of national and economic security. They’re ubiquitous in our smart technologies, high performance materials and industrial catalysts. Yet reclaiming them is complex, dangerous and expensive.

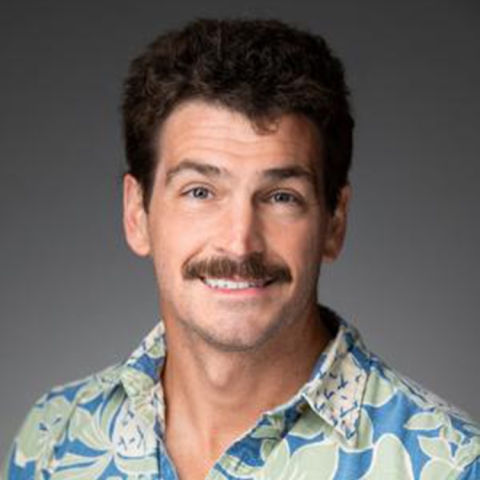

That’s why UC Santa Barbara’s Justin Wilson has partnered with the mineral recovery company REEGen. “We’ve developed a new approach to extract rare earth elements from end-of-life products like electronic waste from phones, batteries and discarded catalytic converters,” said Wilson, a professor in UCSB’s Department of Chemistry & Biochemistry. The new technique, published in Communications Chemistry, combines the strengths of solid-state extraction with precision chemistry. The goal is to make rare earth element recycling financially, logistically and environmentally attractive.

Back to the Periodic Table

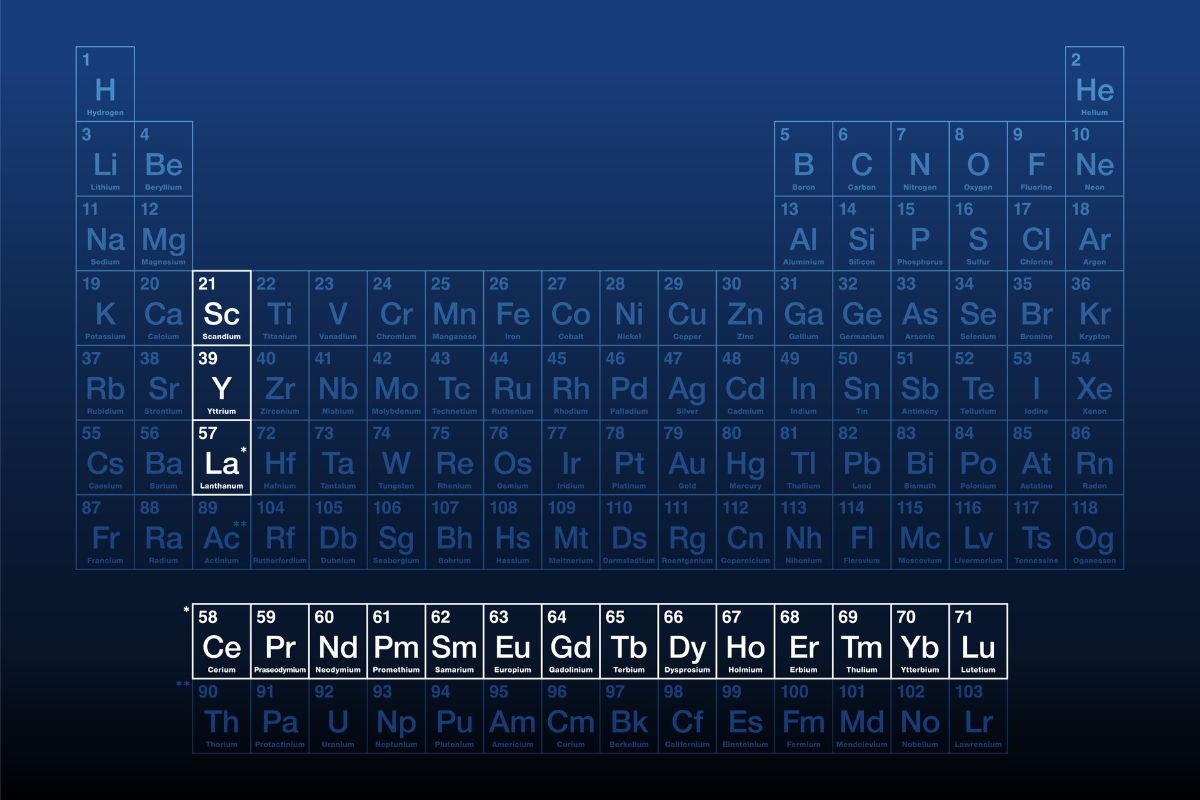

The rare earth elements (REEs) encompass scandium, yttrium and the elements from lanthanum through lutetium. They sit deep within the periodic table, in the section that’s often excised and placed underneath.

Although not as rare as their name suggests, the REEs are difficult to obtain in their pure forms. Recovering them from geologic deposits or waste materials is a multi-step process that involves dissolving the feedstock, removing all of the other metals and then isolating each REE individually. “Unfortunately, their chemical similarities make them fiendishly difficult to separate from one another.

Wilson’s lab focuses on compounds called chelators, which bind to metals like a crab claw grabbing a pebble. In 2024, his team synthesized a unique chelator, called G-macropa, that preferentially binds to large metal ions, like the hefty REEs. His team was able to apply this molecule to separate different REEs from another at room temperature without relying on the toxic and caustic compounds currently used for the task. Now Wilson has turned his attention toward the initial step of concentrating rare earth elements from a mixture containing many different metals.

Combining precision chemistry with a simple setup

Scientists at REEGen have engineered microbes to produce organic acids and bio-chelators that the company uses to leach rare earth elements from waste streams. Wilson’s expertise comes in after this initial extraction to separate the REEs from other metals in the bio-leachate, such as alkali metals and alkaline earth metals, as well as iron and aluminum.

Wilson wanted to develop a simple material that could remove the REE ions from the bio-leachate much like a water filter removes metal ions from tap water. He already had the macropa chelator, his team just had to figure out how to modify it to stick to a resin scaffold without losing the molecule’s useful properties.

The concept of using a resin or material to remove metal ions is well known. For instance, Brita filters can remove metal ions from tap water and water softening units in homes can capture calcium and magnesium. The approach by Wilson's lab, however, sought to leverage the unique selectivity of the macropa chelator for very large REEs to develop a resin that could remove these critical elements, while leaving other metal ions relatively untouched.

Once Wilson’s lab successfully attached the macropa to the scaffold, they ran REEGen’s bio-leachate through the device. This process increased the concentration of rare earth elements fourfold —from 5% by number of atoms (or molar percentage) to over 21 mol%. Adding oxalate to remove excess iron further improved this, resulting in a solution with nearly 59 mol% REEs. A simple rinse with hydrochloric acid detaches the ions from the framework, and it’s ready to be used again.

Addressing an unmet need

“The rare earth elements are critical components of many high-tech materials, but their extraction from raw ores is not economically and environmentally friendly,” said lead author Yangyang Gao, a postdoctoral researcher in Wilson’s lab. “We are dedicated to developing clean and green rare earth extraction, enrichment and separation strategies.”

The authors aim to use their technique to produce concentrated solutions of REEs that can then be sent to a company that separates the individual elements. While some firms have begun to extract REEs from e-waste, rare earth recycling is still in its infancy. “Right now nobody is getting the rare earth elements out of these automotive slags,” said co-author Sean Medin, REEGen’s chief technology officer.

Processing automotive waste requires harsh chemicals that introduce logistical, safety and regulatory complications. As a result, it’s only practical at large scale, and simply not economically attractive right now, Medin explained. A filter is well contained, generates less waste and makes the process simple. “And having a cleaner process makes it a lot easier to set these things up onsite,” he added.

The team hopes to make their technique even more selective for REEs and modify the setup to work with a variety of leachates.

The technique lends itself to sundry applications, including resource extraction, recycling and even environmental remediation. “There could be a certain degree of modularity here,” Wilson said. “If we have different chelators and figure out how to attach them here, we could start to target different metal ions, like mercury, cadmium and lead.”

Cost is currently the limiting factor. Macropa is a challenging molecule to make, requiring many steps to create. The more complicated the process, the less attractive it is for industrial applications. But Wilson’s lab is working to capture the properties of macropa in other, simpler chelators. They’re also searching for a more optimal resin to further improve efficiency.

Despite their accomplishments, the team is concerned that their progress might suddenly grind to a halt. This work was funded by the National Science Foundation’s Small Business Innovation Research grant, as well as the Department of Energy’s Basic Energy Sciences program. “These funding agencies, which are under considerable threat, are crucial to important areas for national security, like supporting a domestic supply of rare earth elements,” Wilson said.

The federal government has stated that domestic production of REEs is a priority, “However, they’re cutting the agencies that are funding the work to do this,” Medin added. Rolling back regulations may incentivize mining, but that’s not necessarily the most efficient way to source these elements.

“With significant cuts to these federal funding sources, I think we’re going to be hurting as a nation,” Wilson said.