Printing Protection

As the U.S. works to stem the tide of COVID-19 infections, calls echo across the country from hospitals and service workers in desperate need of protective masks.

Researchers at UC Santa Barbara are responding.

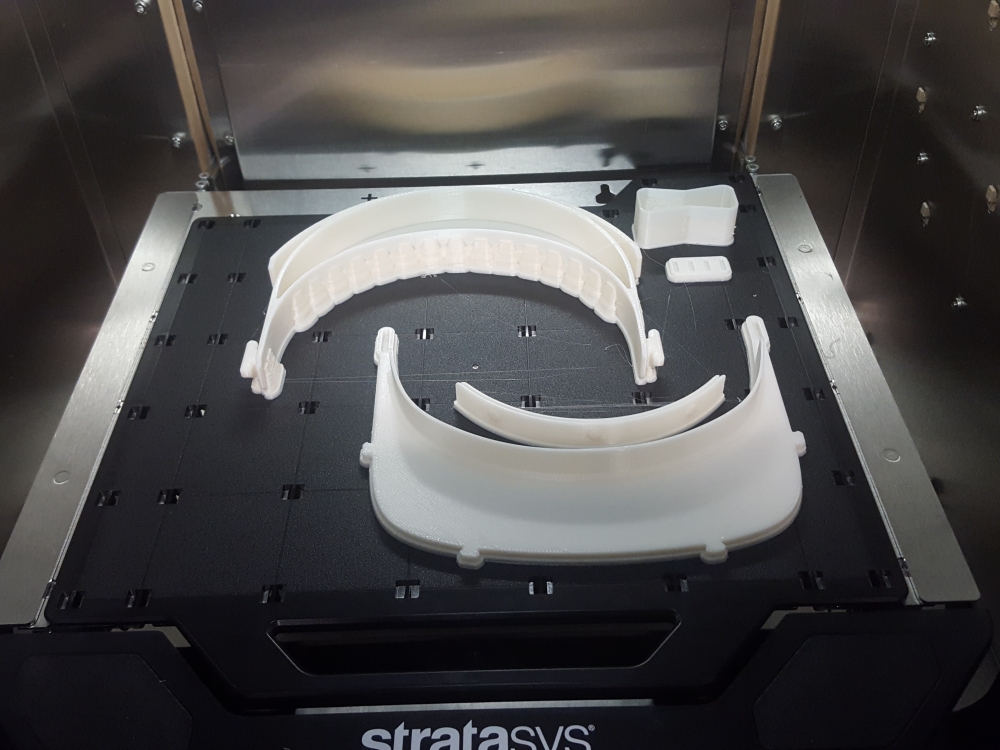

The university’s California NanoSystems Institute (CNSI) has begun 3D-printing face shields to augment other protective equipment worn by health professionals. They join a growing trend of scientists and engineers who have sidelined their own work in favor of supporting the community through this crisis.

David Bothman, manager of CNSI’s Microfluidics Lab and the Innovation Workshop, is spearheading the effort. “In the course of one day, four faculty members who are familiar with the workshops and had read about the work being done elsewhere around the world, got in touch with references, contacts and offers to help,” he said.

The lab is currently prototyping three different designs of face shields, which provide additional protection to healthcare workers in concert with breathing masks and goggles. According to Bothman, the lab can make about 10 of the more complex designs per day, and probably 100-200 per day of the simpler design. They’re also working on sourcing the material for the 3D printers, which has become a bit more difficult as of late. The simplest design can be made with scissors and a stapler, the more complex designs require the use of the lab’s 3D printers and laser cutter. They are more durable, and may be easier to disinfect.

Bothman reached out to Santa Barbara Cottage Hospital offering to help coordinate engineers and technicians on campus to assist in whatever ways that they can. To that end, he created an online portal where people on campus can sign up to help.

“UCSB’s commitment to help is tremendous,” said Bothman. “Labs have made hand sanitizer to use on campus — our lab made a gallon to distribute last week to people working in offices, and to some students who are still on campus.”

Usually the CNSI Microfluidics Lab and the CNSI Innovation Workshop are busy with campus researchers building parts for their experiments, but “because of UCSB’s COVID-19 rules the labs are closed,” Bothman said, “so I’m doing this work alone in the lab to prevent any chance of workers infecting each other.”

CNSI has built some tremendous workshops where faculty, staff and students at UC Santa Barbara can build scientific instruments and prototypes of their inventions. The lab currently has about 300 users from 90 different research groups and CNSI Incubator companies. Their facilities include 3D printers, laser cutters and other tools that are well suited for rapid prototyping.