Scientists’ Research into Friction Provides Insight Into the Mechanics of Arthritis

A new, noninvasive, and low-cost method for the early detection and monitoring of osteoarthritis (arthritis caused by wear and tear) may be on its way, thanks to research by UC Santa Barbara scientists from the Department of Chemical Engineering and the Department of Materials.

By studying patterns of friction between cartilage pads, the researchers discovered a different type of friction that is more likely to cause wear and damage. Their work suggests ways to detect this friction, and points to new research directions for getting to the root cause of arthritis. The findings are published in the recent issue of the Proceedings of the National Academy of Science.

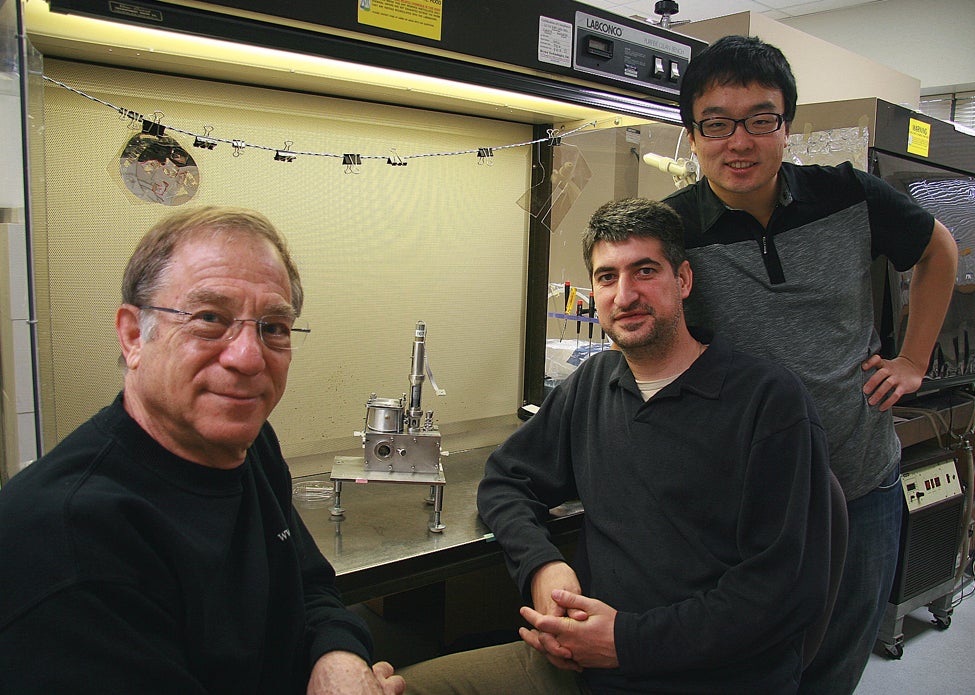

Imagine going to the doctor for your aching knees. For some, this may involve uncomfortable needle sticks to draw blood for lab tests, or the extraction of the fluid surrounding the aching joint. But what if your doctor could actually listen to your body, monitoring the way your knees sound as they bend and flex? Research by Jacob Israelachvili, UCSB professor of chemical engineering and materials science; grad student researcher Dong Woog Lee; and postdoctoral researcher Xavier Banquy says that it's possible.

For their work, they used an instrument called a Surface Forces Apparatus (SFA), a device that measures the adhesion and friction forces between surfaces, in this case cartilage –– the pad of tissue that covers the ends of bones at a joint. The degeneration of cartilage is the most common cause of osteoarthritis –– the pads wear away, leaving bone grinding against bone.

What the researchers found is that it isn't just any kind of friction that leads to the irreversible wear and tear on the material. "It is currently believed that a high-friction force, or ‘coefficient of friction,' is the primary factor in surface wear and damage," said Israelachvili. "What we found is that this is not the case."

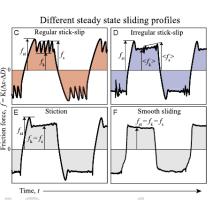

The critical feature is not a high-friction force, but what is known as "stick-slip" friction, or, sometimes, "stiction." Both are characterized by surfaces that initially stick together, and then accelerate away quickly once the static friction force is overcome. With stick-slip friction, the surfaces eventually pull slightly apart and slide across each other, stick again, and pull apart, causing jerky movements.

"That's when things get damaged microscopically," said Israelachvili.

Stick-slip is a common phenomenon. It is responsible for everything from computer hard drive crashes and automobile failures, to squeaking doors and music.

"The same thing happens with a violin string: Even if you're pulling the bow steadily, it's moving in hundreds or thousands of little jerks per second, which determine the sound you hear," Israelachvili said. Each little jerk, no matter how submicroscopic, is an impact, and over time the accumulation of these impacts can deform surfaces, causing irreparable damage –– first microscopically, then growing to macroscopic (large, visible) dimensions. That's when you have to change the string.

But it's not easy to tell the difference between types of friction at the microscopic level, where it all begins. Smooth-sliding joints might feel the same as those undergoing stiction, or the even more harmful stick-slip, especially in the early stages of arthritis. But, when measured with an ultra-sensitive and high-resolution instrument like the SFA, each type of friction revealed its own characteristic profile: Smooth-sliding joints yielded an almost smooth constant line (friction force or friction trace); joints with stiction showed up as a peak, as the "sticking" was being overcome, followed by a relatively smooth line; while stick-slip shows the jagged saw-tooth profile of two surfaces repeatedly pulling apart, sticking, and pulling apart again. According to the scientists, these measurements could be recorded by placing an acoustic or electric sensing device around joints, giving a signal similar to an EKG.

"With a well-designed sensor, this could be a good way to measure and diagnose damage to the cartilage," said Banquy. It could be used to measure the progression, or even the early detection of symptoms related to arthritis.

For a country that's facing a geriatric population explosion, dealing with issues associated with old age is no small matter. Early detection of conditions like arthritis has been a priority for many years, as baby boomers advance in age.

However, the functioning of joints is more complicated, said Israelachvili. The scientists will continue their work by studying synovial fluid –– the lubricating fluid between two cartilage surfaces in joints –– that also plays a major role in whether or not the surfaces wear and tear, and the synergistic roles of the different molecules (proteins, lipids, and polymers) that are all involved in lubricating and preventing damage to our joints.

"There are a number of directions to take, both fundamental and practical," Israelachvili said. "But it looks as if we need to focus our research on finding ways to prevent stick-slip motion, rather than lowering the friction force."

† Top image: From left, Jacob Israelachvili, Xavier Banquy, and Dong Woog Lee with the Surface Forces Apparatus

Photo by Sonia Fernandez

†† Bottom image: Steady-state sliding profiles illustrate the different types of friction. Smooth sliding (F) illustrates very low friction forces, while the jagged profile of regular stick-slip friction (C), shows how surfaces stick, slide, and then stick again repeatedly.